Columbia Fruit Packers, Inc. cherries are packed with care.

Take the journey a cherry goes on once it's picked fresh from the orchard. From picking, sizing, drying to packing, there are many steps to bring quality fruit to the consumer. Columbia Fruit Packers, Inc. makes sure that the highest level of care is taken with every step.

The cherry season usually ranges from the first of June until the end of July, first of August.

Cherries are checked for size and color, before a decision is made to pick.

Once picked, red cherries are usually packed directly into plastic bins for delivery. Rainiers are put into lugs and then placed into bins.

Once the cherries are in the bins, they are ready to be loaded onto a truck and delivered to Columbia Fruit.

Once delivered the fruit is handled by the receiving department. It gets weighed and a ticket is generated. It then goes into a cold room and waits to be run.

Samples are pulled from each grower's fruit as it goes across the receiving line. The receiving crew then prepares an analysis of the fruit based on condition and size.

Here a bin is being dumped into the water to begin the process. At this stage the cherries are taken from the bin up a line over to the sorting tables.

Here is a picture of the sorting tables. The fruit is run through tubes into each sorting table where employees wait to sort through the cherries.

The employees check for any problems that may make a cherry unpackable. Some of the problems the employess look for are the size of the cherry, the color, and if there are any defects. These cherries are then removed from the packable cherries.

After a cherry has been sorted they will move onto the sizing area of the line.

This picture is showing the cherries being shaken apart before they are sized.

Throughout this process each grower is still having samples taken of the cherries to ensure that the quality is meeting the correct standards.

This picture is showing cherries after they have been through the accrowsizer and are on their way to filling stations where they will be packed for sale.

Here is an overview of the where the cherries are being packed into boxes.

Here is a close up of a filling station, where the filler will use equipment to ensure that the correct amount of cherries are being placed into each carton that is shipped out.

Once the boxes are complete, they are run through a stamping station where each box goes through the final process before it is ready to be shipped.

Here is a picture of the final product. From the trees, into the boxes, into the consumers home.

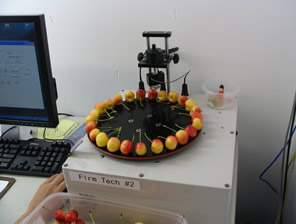

Rainiers are also sampled the same as red cherries. Here you see them being tested on a Firm Tech machine for firmness and size.

When Rainiers are packed they are brought into the warehouse in lugs. They are then dumped by hand into the water where they travel to sorting tables.

Rainiers are sorted by hand. Since Rainiers are more delicate it can take longer for bins to be dumped and packed.

Once they are sorted they are placed into boxes, weighed, and ready to be shipped.